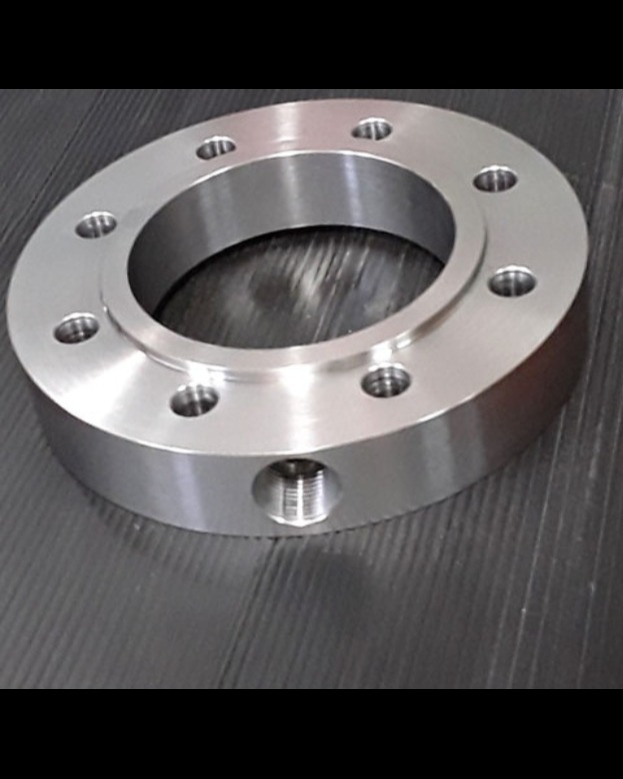

Stainless Steel Bleed Ring manufacturer Stainless steel bleed ring is the corrosion resistant and is installed between two valves, acting as a pressure releasing rings. This ring has the face which can be matched with any flange type and even the sizes are different. This can be used with the valve in order to slow down or shut off the pressure of valve before removing flange Equipped with a standard NPT tap (custom tap sizes available), this bleed ring allows quick access to system pressure or fluid content without disturbing the pipeline. Compatible with raised face and flat face flanges, it’s a critical tool for pressure monitoring, drainage, or flushing operations. Bleed ring flanges, also known as drip ring flanges or bleeder flanges, are specialized components used in piping systems to facilitate the venting, draining, or sampling of fluids. These flanges are typically installed between standard flanges, valves, or other equipment within a pipeline. Bleed ring flanges play a vital role in providing controlled access points within piping systems for activities such as bleeding, draining, or sampling fluids, thereby contributing to the efficient and safe operation of industrial processes while allowing for necessary maintenance and testing procedures. Standard Specification For Bleed Rings Dimensions : ASME B16.50 - ASME B16.20 - ASME B16.48 Size : 1/2' - 24' AND 1 13/16” - 4 1/16” Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6, 10, 16, 25, 40 Etc. Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) Material & Grades of Bleed Rings : Stainless Steel Bleed Ring : ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L Duplex & Super Duplex Steel Bleed Ring : ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 Carbon Steel Bleed Ring : ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 Low Temperature Carbon Steel Bleed Ring : ASTM A350, LF2, LF3 Alloy Steel Bleed Ring : ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 Copper Alloy Steel Bleed Ring : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200 Nickel Alloy Bleed Ring : ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) Why Use Bleed Ring Flange 1) Preventing Contamination 2) Pressure Relief 3) Leakage Detection 4) Inspection 5) Flange Maintenance stainless steel bleed rings bleed rings stainless steel 304 stainless bleed ring 316 stainless steel bleed ring bleed rings for flanges bleed ring manufacturers bleed ring suppliers Hence Stainless steel bleed rings are essential components in any piping system where pressure relief, sampling, or chemical injection is required without disrupting the flange connection. Whether you're working in oil & gas, chemical processing, power generation, or water treatment, these devices provide a safe and efficient way to access internal system pressure. If you have any requirement, please send us on sales@sagarsteel.net or call us on +91 9920177883

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sagarsteelcorporation.com/latest-update/stainless-steel-bleed-ring-manufacturer/553

Stainless Steel Bleed Ring manufacturer

2025-10-17T05:32:56

Stainless Steel Bleed Ring manufacturer Stainless steel bleed ring is the corrosion resistant and is installed between two valves, acting as a pressure releasing rings. This ring has the face which can be matched with any flange type and even the sizes are different. This can be used with the valve in order to slow down or shut off the pressure of valve before removing flange Equipped with a standard NPT tap (custom tap sizes available), this bleed ring allows quick access to system pressure or fluid content without disturbing the pipeline. Compatible with raised face and flat face flanges, it’s a critical tool for pressure monitoring, drainage, or flushing operations. Bleed ring flanges, also known as drip ring flanges or bleeder flanges, are specialized components used in piping systems to facilitate the venting, draining, or sampling of fluids. These flanges are typically installed between standard flanges, valves, or other equipment within a pipeline. Bleed ring flanges play a vital role in providing controlled access points within piping systems for activities such as bleeding, draining, or sampling fluids, thereby contributing to the efficient and safe operation of industrial processes while allowing for necessary maintenance and testing procedures. Standard Specification For Bleed Rings Dimensions : ASME B16.50 - ASME B16.20 - ASME B16.48 Size : 1/2' - 24' AND 1 13/16” - 4 1/16” Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6, 10, 16, 25, 40 Etc. Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) Material & Grades of Bleed Rings : Stainless Steel Bleed Ring : ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L Duplex & Super Duplex Steel Bleed Ring : ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 Carbon Steel Bleed Ring : ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 Low Temperature Carbon Steel Bleed Ring : ASTM A350, LF2, LF3 Alloy Steel Bleed Ring : ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 Copper Alloy Steel Bleed Ring : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200 Nickel Alloy Bleed Ring : ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) Why Use Bleed Ring Flange 1) Preventing Contamination 2) Pressure Relief 3) Leakage Detection 4) Inspection 5) Flange Maintenance stainless steel bleed rings bleed rings stainless steel 304 stainless bleed ring 316 stainless steel bleed ring bleed rings for flanges bleed ring manufacturers bleed ring suppliers Hence Stainless steel bleed rings are essential components in any piping system where pressure relief, sampling, or chemical injection is required without disrupting the flange connection. Whether you're working in oil & gas, chemical processing, power generation, or water treatment, these devices provide a safe and efficient way to access internal system pressure. If you have any requirement, please send us on sales@sagarsteel.net or call us on +91 9920177883

2025-10-17T05:32:56

Submit Your Enquiry